R&D Consultation

Access our “Know How”

Our experts are well versed in the design of transvaginal meshes, orthopedic implants, cardiopulmonary bypass machines, antimicrobial coatings, as well as method validation testing, 3D scanning for metrology, 3D motion sensing, functional testing and wear analysis techniques. We are regularly asked to provide solutions to problems that do not yet have answers, serving as product design consultants.

Computer Driven Design Optimization

Are you an entrepreneur who demands nothing short of perfection from your R&D efforts?

When designing a product, you are often faced with design compromises that the human brain is incapable of analyzing. Suppose the widget you want to build needs to run cool, have a long battery life, be cheap, be light-weight, last a long time, and minimize the use of hazardous materials. These attributes all have complex interdependencies. How does the design team know they have optimized all of these attributes to result in the best overall product? In most cases, they take a guess, and develop a “good enough” product.

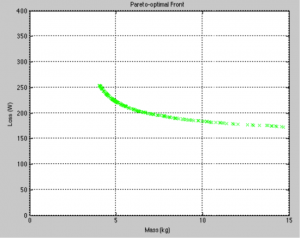

But your competition can make a good enough product too. If you want perfect optimization it may be appropriate to employ advanced computer simulation techniques. We have the ability to perform state of the art population based design methods such as Genetic Algorithms. This advanced technique takes advantage of today’s high power computing availability to model products as species. In simple terms, it works like this. The design team defines attributes of a “fit” species. The computer program allows the species to evolve through many generations, even inserting ‘gene mutations’ along the way to encourage the algorithm to explore combinations that designers may have never considered. A simulated ‘natural selection’ favors the most genetically fit ‘individuals’ for reproduction, resulting in a tendency to pass along favorable traits to the next generation. The result is often presented as a “pareto-optimal front”, or a set of product designs that are each different, but each perfectly optimized. The below image shows the pareto-optimal front for an electronic product showing all optimal combinations of product weight and electrical losses (inefficiency).

Contact us for a free demonstration.